Includes sections on how to use magnet and vacuum lifting devices and how to operate a mobile crane in cold weather. ( Module 21305)Īdvanced Operational Techniques( 20 Hours) Covers multi-crane lifts, critical lifts, blind lifts, and demolition. 550(g) requirements while presenting advanced operation techniques for hoisting personnel. Hoisting Personnel ( 20 Hours) Examines ASME B30.23 and. Standard for Design SPANCO Gantry Cranes are designed to provide dependable, durable lifting solutions.

MULTIPLE CRANE LIFT CALCULATIONS MANUAL

Track Mounted Gantries Appications requiring lifting and moving of heavy loads over a fixed route, either manual or motorized. Provides step-by-step guidance in the assembly and disassembly of lattice booms.( Module 21306) lifting parts and equipment into position. Assess the wind and weather to ensure the safe operation of the multiple crane. Crane Planner 2.0 helps you to take all eventualities into account and to find solutions in advance so that you can carry out your lift in the best possible way. But even supposedly simple lifting operations using mobile and crawler cranes can turn out to be more complicated than initially expected. Determine communication methods and test those communication methods prior to commencing the lift. LIFTS IN THE USA A two crane or tandem crane lift is where two cranes are used to support a load where their hooks are attached directly to an equalizer beam or to the load by slings or lugs. Planning a heavy lift is a demanding task. Select personnel with appropriate qualifications and experience to undertake the lift. Lattice Boom Assembly and Disassembly ( 20 Hours) Identifies lattice-boom components and provides pre-/post-assembly considerations. Assign cranes that meet the lift criteria specified in the planning.

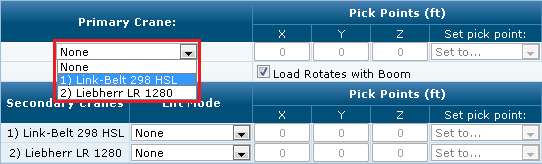

Includes the description and operating characteristics of manual and power luffing jibs.( Module 21302) The first number is the crane’s load capacity for the given boom length and lift radius. Looking at where these rows and columns meet, you’ll see two numbers in each cell. The top row signifies the length of the boom. In average there is need for a 261 ton crane. As mentioned above, the left column signifies the lift radius. Recommended crane size is based on general lifting capacities of cranes with telescopic booms. The load on each crane is calculated throughout the lift. Weight should include the weight of the cargo, lifting gear and hook. As the primary crane moves, the trailing cranes automatically adjust to accurately simulate your lift. Telescopic Boom Attachment Assembly and Disassembly ( 20 Hours) Covers the setup and stowing of swing-away extensions and various jibs, as well as the assembly of intermediate boom sections, on telescopic cranes. Selection of the final crane size should be made in consultation with one of our coordinators. Lift Planning ( 30 Hours) Discusses lift plan implementation, including reference information, calculations, single- and multiple-crane lifting, critical lifts, and engineering considerations.( Module 21304) Covers parts of line and capacity calculations. Includes on-rubber, on-outrigger, jib, and deduction charts, as well as range diagrams and operational notes. The writer hold no responsibility to any misdeeds.Load Charts ( 35 Hours) Discusses the importance of load charts and charts that apply to different configurations. The details obtained by using this method will allow you to ensure that the whole lifting was performed well inside the cranes radius.ĭisclaimer : The above stated information is solely for the purpose of reference additional factors such as ground conditions,Proximity hazards all are to be taken into account for. Work out the obtained data along with the cranes rated duty charts while preparing the lift plan.Take account of the radius, boom length and other contributory factors(See my Blog on Selection of cranes and calculating the Gross load).

Now u have the value of F1 to calculate F2, Subtract "F1" from "P" (weight of load) '''c''' is the distance between the leftmost to the position of the cog (center of gravity) (M)ġ.- The resultant force acting on the object is zero.Ģ.- The sum of the moments acting on an object must be zero.į1 x (c-a) = (P x (l-b-c)) - (F1 x (l-b-c)) '''b''' is the distance between the rightmost to the position of the sling from crane number 2 (M) '''a''' is the distance between the leftmost to the position of the sling from crane number 1 (M) '''F2''' is the weight soported by crane number 2 (Tons) '''F1''' is the weight soported by crane number 1 (Tons) between hooks should be calculated where the first crane reaches its. '''P''' is the weight of the piece (Tons) A two crane or tandem crane lift is where two cranes are used to support a load. Reducing the crane lifting cycle or maximising utilisation of a tower crane can not only increase the productivity but also helps in reduc- ing total project.

0 kommentar(er)

0 kommentar(er)